An Development of Load Cells: An Exploration Through Weighing History

A chronicle of weighing technology is a fascinating odyssey that reflects human creativity and the requirement for exactness across various sectors. At the center of this progress lies the load cell, a crucial part that has changed how we assess mass and pressure. From early mechanical weighing systems to the modern advanced electronic devices, load cells have been at the forefront of precision and dependability, adapting to the needs of current technology.

Among the various types of load cells, the petroleum industry load cell and strain gauge load cell stand out for their specific applications. These instruments play a vital role in maintaining the safety and effectiveness of activities in harsh environments. Understanding the evolution of load cells not only highlights the advancements in design but also showcases the key role these instruments play in diverse sectors, from manufacturing to resource extraction. As we explore further into this story, we will examine the innovations, applications, and the outlook of load cells in our constantly evolving world.

Understanding Oil Field Load Cell s

Petroleum weight measurement devices perform a critical role in the petroleum industry, where accurate weight readings are necessary for operations and safety. These specialized load cells are designed to withstand the hostile conditions of oil fields, including severe temperatures, elevated pressures, and contact to corrosive substances. Their durable construction ensures dependability and precision, facilitating various functions such as borehole operations, conveyance, and repository of petroleum and gas.

One of the primary roles of oil field weight measurement devices is to observe the weight of drilling equipment and payloads. Exact weight measurements are vital for preventing machinery overload, which can cause to catastrophic failures and hazard hazards on site. By utilizing advanced stress measurement technology, these weight measurement devices can deliver real-time data, allowing operators to execute informed decisions that enhance functionality efficiency and security throughout the extraction process.

Moreover, petroleum load cells are designed for easy incorporation with existing monitoring frameworks. This adaptability allows for seamless data collection and analysis, which is essential for optimizing production and minimizing downtime. As the industry continues to advance with improvements in tech, the role of load cells will remain integral to enhanced operational efficiency and better safety measures in the demanding oil field landscape.

This Field of Strain Measurement Technology Load Cells

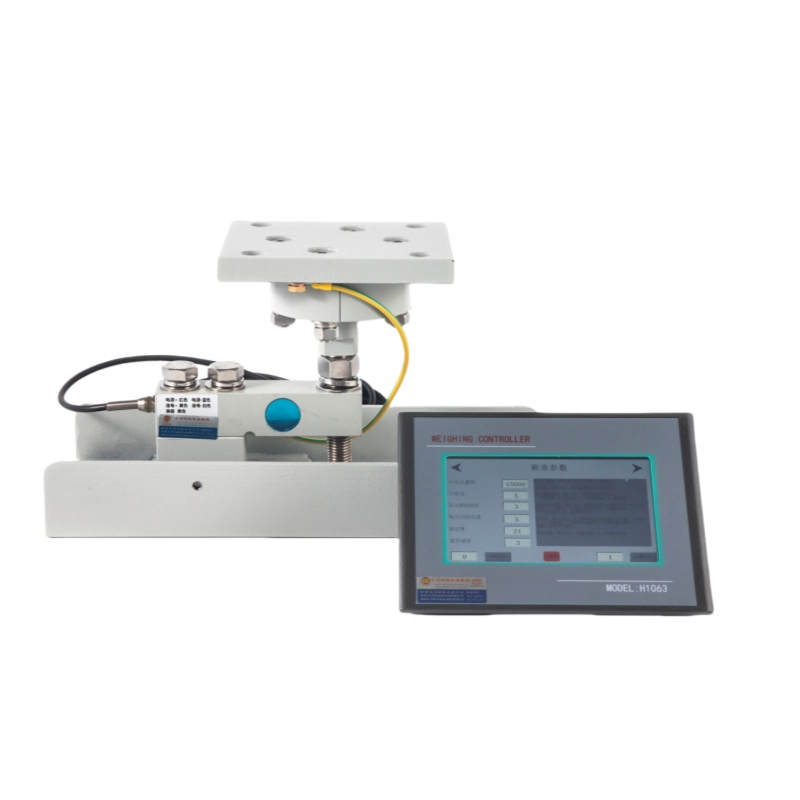

Strain measurement load cells are crucial in the area of weight measurement and force measurement. Such devices operate based on the concept of strain gauges, which measure deformations in materials. When a load is placed to the load cell, it bends or stretches slightly, causing changes in the resistance of the strain gauges. This change in resistance can then be quantified and converted into an electrical signal that correlates to the amount of force being exerted. The precision of this measurement makes strain measurement load cells indispensable in various industrial applications.

One of the key benefits of strain measurement load cells is their flexibility. They can be designed to handle a various weighing capacities and can be customized to specific environmental conditions. Whether used in production lines, heavy equipment, or even in research environments, these load cells provide consistent and accurate readings. Furthermore, progress in material science and sensor technology have led to the creation of load cells that are not only highly precise but also more durable, ensuring longevity and minimal maintenance.

The tuning of strain measurement load cells is essential for ensuring their precision. Calibration involves matching the load cell’s output to a known weight to establish a correlation between the input force and the electrical signal produced. Frequent calibration is important to maintain precision over time, especially in conditions where loads may frequently vary. Thus, strain measurement load cells continue to be at the leading edge of weighing technology, enabling industries to track and control their processes with assurance. ### Advances and Future Directions in Load Cell Technology

Load cell technology is continually evolving, driven by the need for increased precision, dependability, and adaptability across multiple sectors. One major development is the development of smart load cells that feature built-in sensors and wireless connectivity. These smart systems allow for instant data transmission along with sophisticated diagnostics, leading to enhanced operational efficiency and proactive maintenance. As industries increasingly adopt the Internet of Things, smart load cells are prepared to play a pivotal role in advancing process automation and gathering data.

Another growing trend is the combination of strain measurement load cells with advanced materials and design techniques to enhance their performance in difficult settings. Technologies such as additive manufacturing and nanomaterials are facilitating the creation of lightweight, yet robust load cells that can withstand extreme conditions, including high temperatures and corrosive environments. This advancement is particularly relevant in industries such as oil and gas, where load cells used in oil fields must provide accurate readings under challenging operational conditions.

In the future, the emphasis on sustainability is likely to shape the direction of load cell technology. Manufacturers are exploring eco-friendly materials and energy-efficient designs to minimize the ecological footprint of load cell manufacturing and usage. As government regulations and consumer preferences for sustainability increase, the integration of renewable energy sources and biodegradable materials in load cell systems could lead to major progress. This dedication to eco-friendliness not only benefits the environment but also positions companies as responsible leaders in their respective fields.